Hope reliability is not an issue with the Atlas. Volkswagen has not been strong for the last decade.In January we were looking at the Telluride and the Palisade. I finally got her to look at the Atlas. Went to the dealerships, took one look at a Telluride and walked away due to it being small. Went and drove the Palisade and the Atlas. The difference was pretty surprising and she wanted the Atlas. So far, it’s been great. Very quiet and smooth and it’s a Volkswagon so I’m pretty confident.

No forums found...

Site Related

Iowa State

College Sports

General - Non ISU

CF Archive

Install the app

Vehicle reliability - best make/models?

- Thread starter simply1

- Start date

No forums found...

Site Related

Iowa State

College Sports

General - Non ISU

CF Archive

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Interesting insights. So if you're stacking up Kia v. Hyundai overall what's your take? We just got daughter 1 a 2018 Hyundai Elantra for her last two years at ISU, had also thought of looking at Kia Forte for her but she really liked the Elantra.

Considering that Hyundai owns Kia, well....LOL

Most of the platforms and drivetrains are shared, but Hyundai for whatever reason doesn't quite have the same negative stigma. That base 2.0L seems to be ok, but make sure you keep fresh oil in them. Actually, you could say that about any car. A lot of this newer stuff seems to be more prone to sludge build up than older models. Might be because they're running the cylinder heads hotter for better combustion and lower emissions, or the lighter weight oils everyone is using today. Unless she's doing a ton of highway driving, I'd stick to 3000-3500 intervals, regardless of what the factory recommends.

Never ever buy a 2012 Chevy Equinox … that might be the biggest piece of **** vehicle ever sold.

The 2010s and 2011s were far worse.

Considering that Hyundai owns Kia, well....LOL

Most of the platforms and drivetrains are shared, but Hyundai for whatever reason doesn't quite have the same negative stigma. That base 2.0L seems to be ok, but make sure you keep fresh oil in them. Actually, you could say that about any car. A lot of this newer stuff seems to be more prone to sludge build up than older models. Might be because they're running the cylinder heads hotter for better combustion and lower emissions, or the lighter weight oils everyone is using today. Unless she's doing a ton of highway driving, I'd stick to 3000-3500 intervals, regardless of what the factory recommends.

Lol, had no clue.

We have a 2015 Chevy Traverse that has been a really solid vehicle for us with practically no issues *knocks on wood* Have about 87,000 miles on it so far and just replaced the original set of brakes on it this year and had the Tires for Life deal with Karls that we got a new set of tires for free last year but nothing else out of pocket expenses for maintenance. We have a 2007 Impala we've been doing some wear and tear repairs on in the past couple years at 118k miles now but still is better than a car payment as it is pretty much our in town car at this point and Covid probably gave us another year or 2 with not driving it as much. Once our youngest is out of daycare next fall we may start shopping around to replace it and buying another Traverse is a real possibility.

Yes but the philosophies, production, and engineering are a lot less closely related than GM sub-lines.Considering that Hyundai owns Kia, well....LOL

Most of the platforms and drivetrains are shared, but Hyundai for whatever reason doesn't quite have the same negative stigma. That base 2.0L seems to be ok, but make sure you keep fresh oil in them. Actually, you could say that about any car. A lot of this newer stuff seems to be more prone to sludge build up than older models. Might be because they're running the cylinder heads hotter for better combustion and lower emissions, or the lighter weight oils everyone is using today. Unless she's doing a ton of highway driving, I'd stick to 3000-3500 intervals, regardless of what the factory recommends.

I have been an exclusive Hyundai owner for almost ten years, never a KIA, and have never had a problem. Let me repeat that: I have never had a problem, even a minor one except a bulb going out or bad fuel causing issues. Hyundai was going gang busters until around 2016 when they failed to realize American appetite for huge SUVs to haul them around. And, lately recalls and some problems friends have had has made me certain to look hard at other options before buying Hyundai again. But so far so good.

Recalls have been plenty for most manufacturers with redesigns, I think that’s probably one of the biggest factors.Yes but the philosophies, production, and engineering are a lot less closely related than GM sub-lines.

I have been an exclusive Hyundai owner for almost ten years, never a KIA, and have never had a problem. Let me repeat that: I have never had a problem, even a minor one except a bulb going out or bad fuel causing issues. Hyundai was going gang busters until around 2016 when they failed to realize American appetite for huge SUVs to haul them around. And, lately recalls and some problems friends have had has made me certain to look hard at other options before buying Hyundai again. But so far so good.

Yes but the philosophies, production, and engineering are a lot less closely related than GM sub-lines.

I have been an exclusive Hyundai owner for almost ten years, never a KIA, and have never had a problem. Let me repeat that: I have never had a problem, even a minor one except a bulb going out or bad fuel causing issues. Hyundai was going gang busters until around 2016 when they failed to realize American appetite for huge SUVs to haul them around. And, lately recalls and some problems friends have had has made me certain to look hard at other options before buying Hyundai again. But so far so good.

There was a day when that was true, but today that's more of a perception than reality, mostly a product of branding. The platforms and drivetrains for at least the last decade are interchangable. The rest of the differences are styling and build quality. (i.e. interior materials like upholstery, carpet, etc.

Good for you on not having a problem. The old engines on the 2010 and older Sonatas were good (both 4 and 6 cyl) but not so good after. The Elantras over the past several years have been good.

These are the engine families to avoid if you're shopping for a used model. In 2020,there's no excuse for bearing issues. That's one of the most basic design components of an engine. Obviously they were cutting corners in the manufacturing process trying to save money. As I mentioned about CAFE standards, if the government would throw those out the window, reliability would immediately improve as they could focus on reliability instead of having to continually push the efficiency envelope.

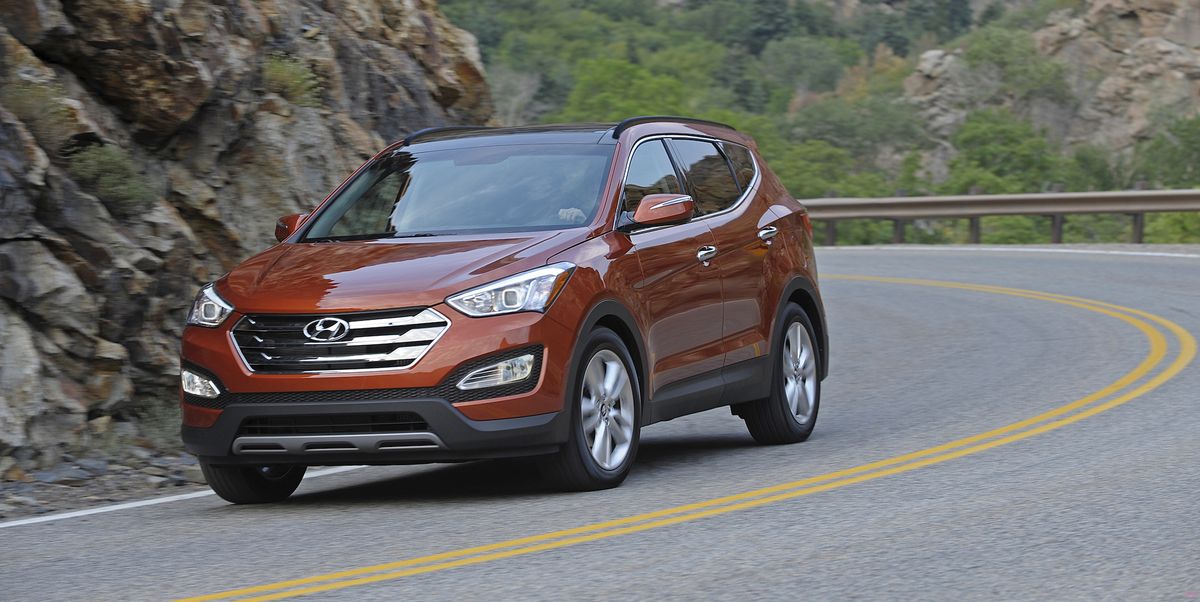

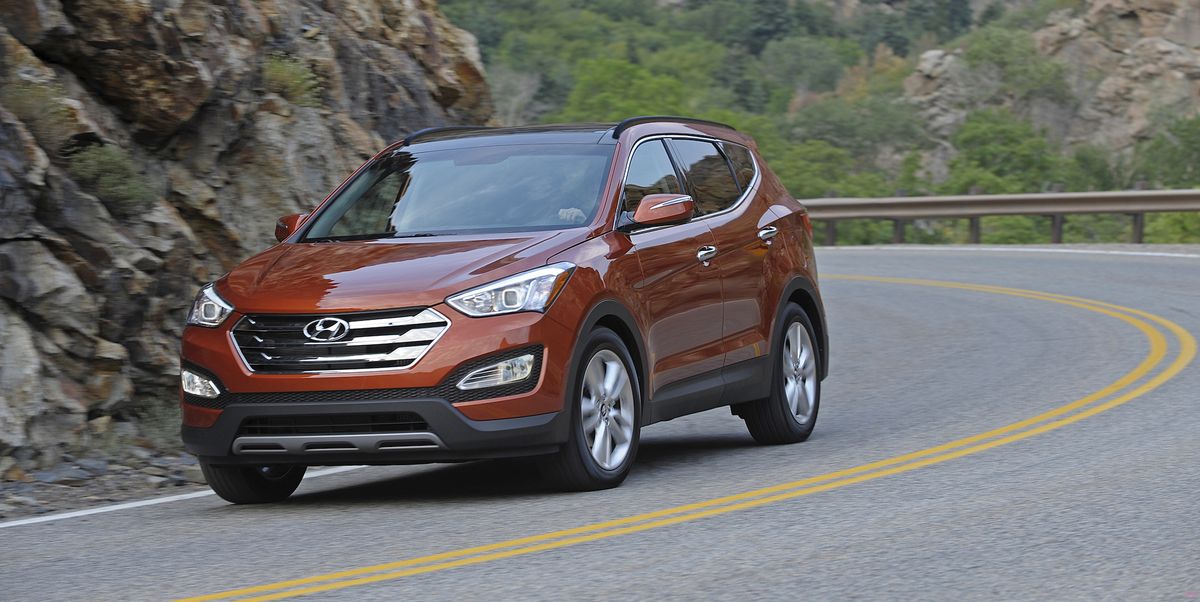

Hyundai, Kia Fined up to $210 Million over Handling of Engine Recalls

NHTSA concluded the automakers didn't respond well enough in recalls of 2011–2014 models including the Santa Fe Sport and Sonata.

I know you need to mention it in every post, but do you really think throwing out the standards is going to happen?There was a day when that was true, but today that's more of a perception than reality, mostly a product of branding. The platforms and drivetrains for at least the last decade are interchangable. The rest of the differences are styling and build quality. (i.e. interior materials like upholstery, carpet, etc.

Good for you on not having a problem. The old engines on the 2010 and older Sonatas were good (both 4 and 6 cyl) but not so good after. The Elantras over the past several years have been good.

These are the engine families to avoid if you're shopping for a used model. In 2020,there's no excuse for bearing issues. That's one of the most basic design components of an engine. Obviously they were cutting corners in the manufacturing process trying to save money. As I mentioned about CAFE standards, if the government would throw those out the window, reliability would immediately improve as they could focus on reliability instead of having to continually push the efficiency envelope.

Hyundai, Kia Fined up to $210 Million over Handling of Engine Recalls

NHTSA concluded the automakers didn't respond well enough in recalls of 2011–2014 models including the Santa Fe Sport and Sonata.www.caranddriver.com

Where do you get your reliability information from? Are engines, major components failing now at a higher rate than the 80s, or is it all of the electronics and safety stuff being added that impacts perception of reliability?

Cars today are light-years more reliable than anything from the 90s or earlier. There was a "blip" of bad reliability when OBD came on the scene in 1996, but that has since been worked out. Part of it is electronics, including things like stereos/nav/screens. Some of that is user error or poorly executed UI. Its not that anything is broken, but people expect to get in and drive and have everything work without reading how to operate it. Sure things break, or wear out, or have quality problems (which is usually put back on the supplier). But a "really bad" reliability part in passenger cars will have maybe a 1% failure rate. There's also a spectrum of drivers, from very gentle and follow the maintenance schedule to the letter, to the drive it like you stole it and only fix it when it starts to smoke. All of that impacts reliability.I know you need to mention it in every post, but do you really think throwing out the standards is going to happen?

Where do you get your reliability information from? Are engines, major components failing now at a higher rate than the 80s, or is it all of the electronics and safety stuff being added that impacts perception of reliability?

I have a 2012 Subaru Outback with 125,000 miles and a 2019 Outback with 26,000. Outside of general maintenance (brakes, tires, timing belt, suspension for the 2012 I really like the Outbacks tough I hate the computer system on the 2019 (cumbersome to use, slow to respond).

My wife wanted a 2019 Subaru Ascent but the Outback was way cheaper. Might go for an Ascent once the lease of the 2019 is up.

My FIL loves Honda CR-Vs. We just bought his 2011 (the kid will get the old Outback) and there isn't a thing wrong with it. He was selling the 2011 to buy a new one.

My wife wanted a 2019 Subaru Ascent but the Outback was way cheaper. Might go for an Ascent once the lease of the 2019 is up.

My FIL loves Honda CR-Vs. We just bought his 2011 (the kid will get the old Outback) and there isn't a thing wrong with it. He was selling the 2011 to buy a new one.

1975 Ford LTD, 46 years old and still going strong. Enough said!

Please post pictures. My parents had a 1976 LTD, which became my car, and to this day it was my favorite vehicle. I drove that until 1995 when it finally died. Easily had over 200,000 miles on it. My god the babies that could have been made in that back seat, but alas my wife will never know!

Last edited:

Cars today are light-years more reliable than anything from the 90s or earlier. There was a "blip" of bad reliability when OBD came on the scene in 1996, but that has since been worked out. Part of it is electronics, including things like stereos/nav/screens. Some of that is user error or poorly executed UI. Its not that anything is broken, but people expect to get in and drive and have everything work without reading how to operate it. Sure things break, or wear out, or have quality problems (which is usually put back on the supplier). But a "really bad" reliability part in passenger cars will have maybe a 1% failure rate. There's also a spectrum of drivers, from very gentle and follow the maintenance schedule to the letter, to the drive it like you stole it and only fix it when it starts to smoke. All of that impacts reliability.

Agreed, cars today always go over 100k easy, 200k yep, some even 300k; cars 20-30 years ago never lasted that long.

Edit: my recent cars have been 2002 Forester 166k, 2010 Prius 225k, and we just bought (6 months ago) a 2015 CX-5 so we'll see how the newest car does it only has 57k

Last edited:

Not calling you out, Turk, but this is what automotive engineers are up against: nostalgia.Please post pictures. My parents had a 1976 LTD, which became my car, and to this day it was my favorite vehicle. I drove that until 1995 when it finally died. Easily had over 200,000 miles on it. My god the babies that could have been made in that back seat, but alas my wife will never know!

People remember all the fun they had in their old cars and forget the times they broke down. Suddenly that old car is "the best car ever" and "they just don't make 'em like that anymore." Well you're right, today's cars are faster, more efficient, more comfortable AND more reliable. They don't make them like that anymore - and thank god they don't!

ETA: In the semi industry, we say "everyone's favorite truck was their dad's truck." And I agree those old Kenworth W900s and Peterbilt 389s looked awesome. But they weren't nearly as capable or reliable as today's trucks.

Last edited:

Not calling you out, Turk, but this is what automotive engineers are up against: nostalgia.

People remember all the fun they had in their old cars and forget the times they broke down. Suddenly that old car is "the best car ever" and "they just don't make 'em like that anymore." Well you're right, today's cars are faster, more efficient, more comfortable AND more reliable. They don't make them like that anymore - and thank god they don't!

ETA: In the semi industry, we say "everyone's favorite truck was their dad's truck." And I agree those old Kenworth W900s and Peterbilt 389s looked awesome. But they weren't nearly as capable or reliable as today's trucks.

I had a ‘77 Cutlass Supreme in high school and a Kia Forte is a much better car.

You also didn’t mention how much safer cars are now. It’s crazy.

Last edited:

I know you need to mention it in every post, but do you really think throwing out the standards is going to happen?

Where do you get your reliability information from? Are engines, major components failing now at a higher rate than the 80s, or is it all of the electronics and safety stuff being added that impacts perception of reliability?

Highly unlikely of the standards getting tossed. It would take a 100% overturn of congress and the WH, and by margins wide enough to be unchallenged for the foreseeable future. In addition there's a lot of cronyism tied to the status quo as well. For example, the ethanol industry benefits from stricter CAFE standards. DC is a kleptocracy.

The best we can hope for is that they leave things where they're at and quit ******* with stuff. At least that way, continual process improvement can operate in the current framework and build a better mouse trap.

Where do I get my reliability info from? Experience. I appraise/buy several hundred cars a month. My core market is vehicles 6-10 years old, so I get to see everything after they're seasoned and the factory warranty is long gone. Much of what I learn comes when I unknowingly buy something that has a problem, but I make an effort to learn from conversations with my peers who inherit similar problems. The industry is so competitive that if you don't know and don't learn, you go broke.

As for your last question, it's a mixed bag. The 80's will forever be known as the worst decade in auto manufacturing history. There were some good cars then, but most were not. Generally speaking, they have gotten more reliable, and electronics have played a large role in that. But there was a sweet spot where the level of electronics was not that advanced and mechanical designs were simple enough to offer good reliability, and more importantly, a lower cost of repair.

IMO environmental regulations have hurt reliability in electronic components as much as anything. Most importantly, the move away from lead based solder used on circuit boards. The solder used today is more brittle, and the net result is that when you put them in cars that are going to be exposed to temps ranging from -20 to 140 and jarred from driving on rough roads, they're going to have a shortened lifecycle. If the failed part is the control module for your power seat, it isn't a big deal. But let's say it's for your power windows, and rather than being part of the master switch, it's hardwired alongside a bunch other modules into your under dash fuse panel (2013 Sorentos) it instantly goes from being a $100 part to a $1900 part. None of those things will leave you stranded, but how exactly do you weigh reliability when a certain repair will cost 5x-10x more when it occurs? But of course they're continually improving circuit board designs as well, and that's a good thing because in 10 years there will be three times as many of them in a new vehicle.

This is all probably WAY more than you wanted to know, but your interest seems genuine. Cars today COULD be even more reliable. But they're not because it a hypercompetitive industry with razor thin margins. The consumer doesn't know what makes one part more reliable and less expensive than another, and even if they did, many would chose to not pay the extra cost. It's a constant balancing act for manufacturers. There's a term coined for how they deal with it. What's it called? Oh yeah, planned obsolescence. lol

I have a 2012 Subaru Outback with 125,000 miles and a 2019 Outback with 26,000. Outside of general maintenance (brakes, tires, timing belt, suspension for the 2012 I really like the Outbacks tough I hate the computer system on the 2019 (cumbersome to use, slow to respond).

My wife wanted a 2019 Subaru Ascent but the Outback was way cheaper. Might go for an Ascent once the lease of the 2019 is up.

My FIL loves Honda CR-Vs. We just bought his 2011 (the kid will get the old Outback) and there isn't a thing wrong with it. He was selling the 2011 to buy a new one.

Those two generations of Crvs (2002-2011) are among the most reliable vehicles ever manufactured. I would put the 2002-2005 Camry and the 2003-2007 Accord in the same category

Cars today are light-years more reliable than anything from the 90s or earlier. There was a "blip" of bad reliability when OBD came on the scene in 1996, but that has since been worked out. Part of it is electronics, including things like stereos/nav/screens. Some of that is user error or poorly executed UI. Its not that anything is broken, but people expect to get in and drive and have everything work without reading how to operate it. Sure things break, or wear out, or have quality problems (which is usually put back on the supplier). But a "really bad" reliability part in passenger cars will have maybe a 1% failure rate. There's also a spectrum of drivers, from very gentle and follow the maintenance schedule to the letter, to the drive it like you stole it and only fix it when it starts to smoke. All of that impacts reliability.

Generally speaking, yes. But there has been some absolute garbage put out in the last 10 years. Transmissions in the Ford Focus, and Nissan Sentra and Versa are two examples of serious regression. Variable cylinder management in Honda V6s and GM V8s are two more, but to a lesser extent.

There seems to be some planned obsolescence at work as well, with manufacturers choosing lighter weight components for fuel economy over reliability. Wheel bearings, control arms, and ball joints would be a few such examples. As I mentioned in another post, reliability is subjective. A sunvisor with a high failure rate isn't as detrimental as a timing chain or a cam phaser. No doubt our engineering capabilities are much better, but it's not necessarily all finding it's way into vehicles. There are some cars from the previous era that are proving to be more reliable than what's been brought to market lately.

I want to like the new Hyundais, but when I was shopping for used school cars and looked at ones with some age on them but reasonable mileage it became pretty apparent that these are not cars engineered to make it past 10 years old, IMO. After the fifth or sixth one I looked at, I changed course and looked only at Hondas and Toyotas. It definitely colored my view of them for my next new car purchase.

I had the economy '14 Accent I bought because it was by far the best mpg for the money in '15 and I had tons of commute miles in an area with crazy high nation leading gas prices.

As early as '18 I got warnings the cat converter was toast. I waited until there was an aftermarket part at $1100 otherwise it would have been $3000 at the time the first light went on.

I guess lots of small Hyundai and Kias from those years run hot, burn oil, and ruin cat converters.

That said the gas mileage might have been underestimated. I got insane mpg. Usually around 38mpg per tank but sometimes barely over 40. Maybe a more reliable economy car would have saved more money but I saved a ton on gas. In hindsight I should have just sold it the first time I had to pass an emissions test with a busted cat, but I know I saved more than that $1100 by driving a very cheap car a ton of miles that got me near 40mpg.

Last edited:

Agreed, cars today always go over 100k easy, 200k yep, some even 300k; cars 20-30 years ago never lasted that long.

Edit: my recent cars have been 2002 Forester 166k, 2010 Prius 225k, and we just bought (6 months ago) a 2015 CX-5 so we'll see how the newest car does it only has 57k

Maybe your issue is like mine in that what you're still calling 20-30 years ago that which is now 35-45.

200k lifecycles have been the norm for a long time. My 87 Sentra made 200k and I spent very little on repairs over the last 100k. Rust was it's demise. Had a 95 Civic that was still running good at 285k, and my old FIL had an 87 Buick Century (used on a gravel road mail route) that made it to 300k. Most of those old Lesabres with the 3.8s were all good for 200k+.

Now with that being said, there were some short cycle cars as well. Head gaskets failing took out a bunch of cars...including ford escorts as well as a plethora of Subarus. Transmissions in Chryslers were terrible.