If you have a shop saw with rollers I agree it's better but I'm always making stuff on site. Two horses, the rip guide and a battery skill saw is so much more convenient in that situation.I have one but haven't used it yet (two years). Table saw is still my go to.

No forums found...

Site Related

Iowa State

College Sports

General - Non ISU

CF Archive

Install the app

Woodworkers Thread

- Thread starter AgronAlum

- Start date

No forums found...

Site Related

Iowa State

College Sports

General - Non ISU

CF Archive

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Also, router rail attachments for tracks are awesome.

I previously mentioned dados for the Dewalt and the few I've had to do, I just used the track and router.

I previously mentioned dados for the Dewalt and the few I've had to do, I just used the track and router.

Ya changing blades on the table saw gets old.Also, router rail attachments for tracks are awesome.

I previously mentioned dados for the Dewalt and the few I've had to do, I just used the track and router.

Nice job!Just finished this for a buddy... installed a couple weeks back. Nothing too special, but what he (his wife) requested & it's always good to make a few bucks to feed the tool addiction.

Also, router rail attachments for tracks are awesome.

I previously mentioned dados for the Dewalt and the few I've had to do, I just used the track and router.

I had no idea these existed but it's good to know they do.

Totally agree. I am strictly a garage/shop worker, not outside on site (except when I do large work on my house), but would use the guide for sure anywhere out of the shop. I bought it intending to use it instead of the table saw on full sheet material, just lazily always pull out the old tried and true instead of using the new method.If you have a shop saw with rollers I agree it's better but I'm always making stuff on site. Two horses, the rip guide and a battery skill saw is so much more convenient in that situation.

The rip guide obviously isn't as precise or consistent but it's marginal. I wouldn't use the rip guide for furniture but it's great for built-ins.Totally agree. I am strictly a garage/shop worker, not outside on site (except when I do large work on my house), but would use the guide for sure anywhere out of the shop. I bought it intending to use it instead of the table saw on full sheet material, just lazily always pull out the old tried and true instead of using the new method.

Lots of 3D printed ones in that $30 range or you can buy a manufacturer specific one. I bought the manufacturer one in case I want to fine tune the distance vs a set 3D one.I had no idea these existed but it's good to know they do.

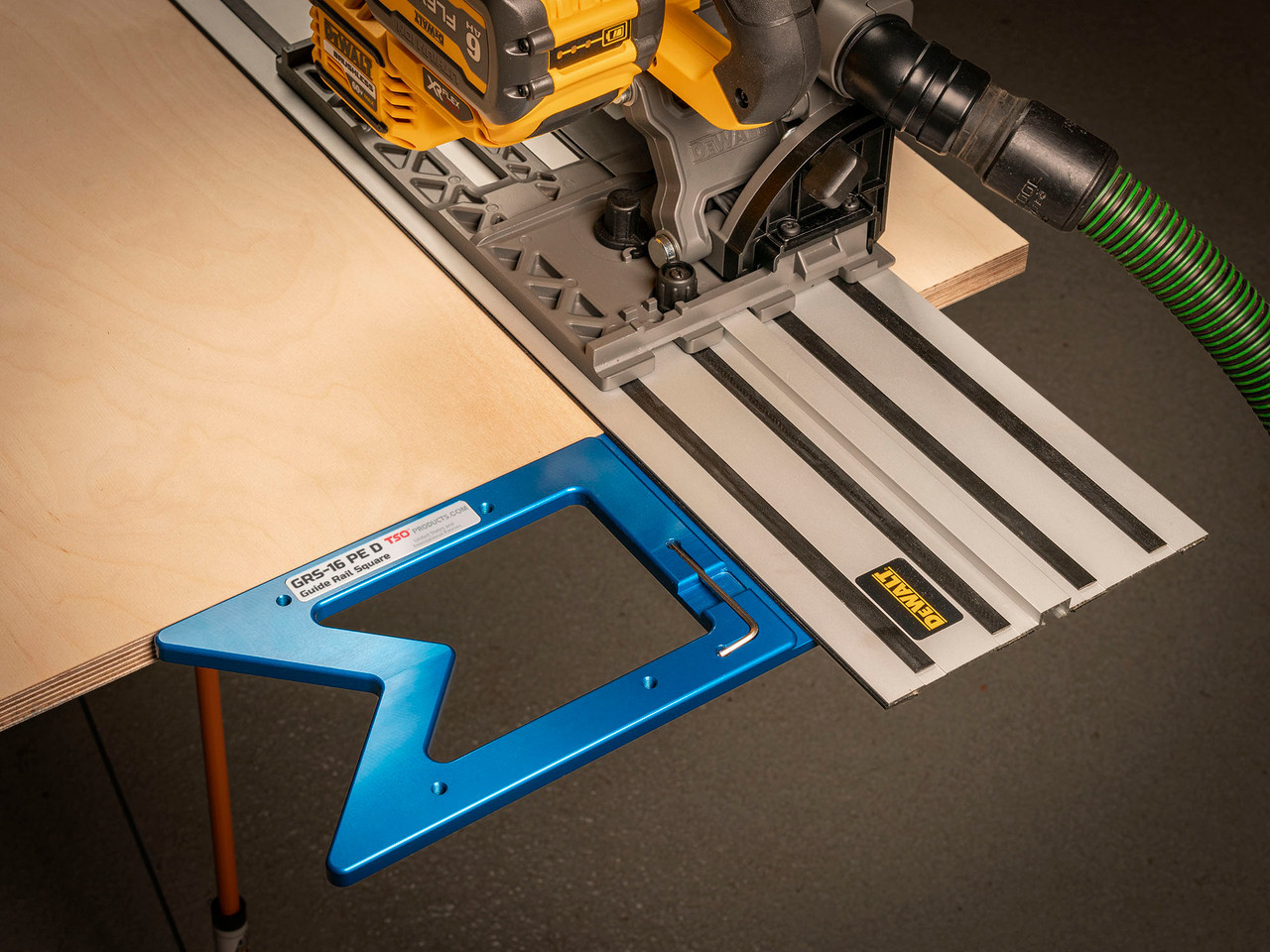

I have also bought one of these for my tracks, which is handy:

When cutting 4x8 sheet, I almost always oversize the first cut or two by 1/8" with either Skil saw or table saw, then cut the smaller piece to finished size when I can control it more precisely. 99% of time I am working alone. I sometimes have the wife step out and give me a hand for a minute, but that carries other consequences.The rip guide obviously isn't as precise or consistent but it's marginal. I wouldn't use the rip guide for furniture but it's great for built-ins.

Yep, I used to do the same but I'm pretty dang good with the rip guide now.When cutting 4x8 sheet, I almost always oversize the first cut or two by 1/8" with either Skil saw or table saw, then cut the smaller piece to finished size when I can control it more precisely. 99% of time I am working alone. I sometimes have the wife step out and give me a hand for a minute, but that carries other consequences.

I have a BOW products fence with Jessem roller guides.When cutting 4x8 sheet, I almost always oversize the first cut or two by 1/8" with either Skil saw or table saw, then cut the smaller piece to finished size when I can control it more precisely. 99% of time I am working alone. I sometimes have the wife step out and give me a hand for a minute, but that carries other consequences.

The roller guides want to "push" the material towards the fence because they are barely off square. That's come in real handy.

Has anybody retired their tablesaw with a tracksaw? I have only fired up my table saw like once in the last couple years since I've mostly been woodturning. I feel like I could easily get rid of it and not miss much especially if I replaced it with a tracksaw. I'd like to have the floorspace in my garage for a project car.

Either way I think I need to do some work or re-arranging my floorplan in that garage stall. I looked at adding a stall but got a couple of eff off quotes back and gave up on that idea.

I stumbled across a great deal on a Festool track saw and I still would never get rid of my table saw. You can do a much nicer job on cuts with a table saw vs a track saw. I just built two large cabinets for a friend and used the track saw to rough cut the panels then finished them to size with the table saw. That's not even accounting for losing the dado functionality (even though you could technically use a router and straight edge (talk about a pain!).

Great conversation today!I stumbled across a great deal on a Festool track saw and I still would never get rid of my table saw. You can do a much nicer job on cuts with a table saw vs a track saw. I just built two large cabinets for a friend and used the track saw to rough cut the panels then finished them to size with the table saw. That's not even accounting for losing the dado functionality (even though you could technically use a router and straight edge (talk about a pain!).

I have a job site table saw and build an extension around it give it more surface area. Like others, I too have the Bow fence and Jessen guides. a lot of times, it works pretty well and is precise. Even with extensive time spent on calibration, checking and re-dialing in for square, etc. etc. - I still find longer boards and longer panel cuts to be a bit wonky. The Jessen guide rails are great when you’re alone but I still (sometimes) get inconsistent results. I think I just expect too much of this job site saw sometimes!

I’ve had the Milwaukee track saw for 6 months and it is by far my favorite tool, maybe ever. I have several tracks - the longest one they offer, a few medium sized Powertec ones, and some smaller ones too. Along with the ‘connectors’ to make them extend if needed. Just glorious to use in nearly every situation. Obvious exception is when I need true parallel repeatability, and I am too cheap to buy the ‘nicer’ parallel guides (although I probably just need to make some myself as I have seen some on YouTube that look pretty reliable and precise). I also use these tracks with my Milwaukee router extensively, as the Milwaukee router rail attachment is pricey but fantastic.

If I can ever upgrade my space (i.e. size of my garage), I would love to get a SawStop or something similar.

Similar question, and maybe this has already been discussed - anyone thinking about ditching the miter saw!? I have the Bosch 12” sliding compound miter saw there is certainly a lot to like, but my goodness the dust collection is awful (even with every “dust collection solution” from Etsy I could find/try), and I still struggle with keeping it calibrated. I wonder if I need to go “full MFT/precision cutting table” with the track saw, hopefully allowing me to have a really nice (and repeatable) cross cut setup, like what you see with Festool or Kreg’s systems. We’ll see… curious what others think?

This thing is expensive but it seems like it might be right up what I'm looking for. I really like the footprint and how many things it looks like you can do with it. I've seen a couple of youtubers who have replaced tablesaws with one too. The dado thing is still the biggest problem but a router attachment for a track would probably solve that if I needed to plow a big long dado into anything.

www.kregtool.com

www.kregtool.com

Adaptive Cutting System Master Kit

Precision cutting system for solid-wood, plywood, and panels Take your project-building skills to the next level with the Adaptive Cutting System Master Kit. It offers all the advantages of guided cutting using a track saw with its high-performance Plunge-Cut Track Saw and Guide Track. But the...

I can't stand sliding miter saws, at least with the work I do. They take up a ton of space, and other than cutting a bunch of stuff to the same length at a perfect 90 degrees I find them to be very inaccurate. If I was framing houses or building decks maybe I'd feel differently though. A lot of fine woodworkers would tell you to get a 12" non slider because there's less tolerance stack in the components because they're fewer moving parts if you have to have a miter saw. I think that kreg set-up I posted above might be a better option but I've yet to mess with one in person. I'm assuming Acme tool or Woodsmith probably has one setup you can look at but I haven't had a chance to make the trip lately.Great conversation today!

I have a job site table saw and build an extension around it give it more surface area. Like others, I too have the Bow fence and Jessen guides. a lot of times, it works pretty well and is precise. Even with extensive time spent on calibration, checking and re-dialing in for square, etc. etc. - I still find longer boards and longer panel cuts to be a bit wonky. The Jessen guide rails are great when you’re alone but I still (sometimes) get inconsistent results. I think I just expect too much of this job site saw sometimes!

I’ve had the Milwaukee track saw for 6 months and it is by far my favorite tool, maybe ever. I have several tracks - the longest one they offer, a few medium sized Powertec ones, and some smaller ones too. Along with the ‘connectors’ to make them extend if needed. Just glorious to use in nearly every situation. Obvious exception is when I need true parallel repeatability, and I am too cheap to buy the ‘nicer’ parallel guides (although I probably just need to make some myself as I have seen some on YouTube that look pretty reliable and precise). I also use these tracks with my Milwaukee router extensively, as the Milwaukee router rail attachment is pricey but fantastic.

If I can ever upgrade my space (i.e. size of my garage), I would love to get a SawStop or something similar.

Similar question, and maybe this has already been discussed - anyone thinking about ditching the miter saw!? I have the Bosch 12” sliding compound miter saw there is certainly a lot to like, but my goodness the dust collection is awful (even with every “dust collection solution” from Etsy I could find/try), and I still struggle with keeping it calibrated. I wonder if I need to go “full MFT/precision cutting table” with the track saw, hopefully allowing me to have a really nice (and repeatable) cross cut setup, like what you see with Festool or Kreg’s systems. We’ll see… curious what others think?

That's a pretty cool system - hadn't seen that before. Could replace quite a few jobs, but would probably make them all take a bit more time than the conventional way. I guess it all depends on how much woodworking you do - if you do a bunch, a bunch of tools is probably the route you go, but if you are seldom woodworking but can spare the extra time something like that may make more sense.This thing is expensive but it seems like it might be right up what I'm looking for. I really like the footprint and how many things it looks like you can do with it. I've seen a couple of youtubers who have replaced tablesaws with one too. The dado thing is still the biggest problem but a router attachment for a track would probably solve that if I needed to plow a big long dado into anything.

Adaptive Cutting System Master Kit

Precision cutting system for solid-wood, plywood, and panels Take your project-building skills to the next level with the Adaptive Cutting System Master Kit. It offers all the advantages of guided cutting using a track saw with its high-performance Plunge-Cut Track Saw and Guide Track. But the...www.kregtool.com

I just built these cabinets a couple weeks ago - used my track saw, table saw, and miter saw and made them in pretty good time. I cannot imagine cutting all those dados with a router.

Attachments

I like to be able to draw the cross cut across the board face once before completely cutting. With hard woods I find that trying to cut it in one sweep results in lots of blade chatter, blade bend and blow outs.I can't stand sliding miter saws, at least with the work I do. They take up a ton of space, and other than cutting a bunch of stuff to the same length at a perfect 90 degrees I find them to be very inaccurate. If I was framing houses or building decks maybe I'd feel differently though. A lot of fine woodworkers would tell you to get a 12" non slider because there's less tolerance stack in the components because they're fewer moving parts if you have to have a miter saw. I think that kreg set-up I posted above might be a better option but I've yet to mess with one in person. I'm assuming Acme tool or Woodsmith probably has one setup you can look at but I haven't had a chance to make the trip lately.

In a shop a non slide makes sense if you have a nice laser or light for accuracy. I think if I had the money I would get a radial arm saw.

I can't stand sliding miter saws, at least with the work I do. They take up a ton of space, and other than cutting a bunch of stuff to the same length at a perfect 90 degrees I find them to be very inaccurate. If I was framing houses or building decks maybe I'd feel differently though. A lot of fine woodworkers would tell you to get a 12" non slider because there's less tolerance stack in the components because they're fewer moving parts if you have to have a miter saw. I think that kreg set-up I posted above might be a better option but I've yet to mess with one in person. I'm assuming Acme tool or Woodsmith probably has one setup you can look at but I haven't had a chance to make the trip lately.

I love my Dewalt compound slider and haven't really noticed any inaccuracies after getting it tuned in. I've also transitioned into more construction type projects for other people than woodworking so that may be part of it. I agree, it is really bulky because it has the two tubes for the slider unlike the Bosch style with the articulating arm.

I just leave it attached to this, fold it up and stash it in the corner. This stand might be my second favorite "tool" purchase lately behind the track saw. If you want to take the saw off, it's just two large tabs holding it in place. Plus I can wheel it outside to do the cutting and not make a mess.

RIDGID Foldable Mobile Miter Saw Stand with Mounting Braces AC9946 - The Home Depot

Complete all your jobsite works easily and efficiently with the addition of this excellent RIDGID Universal Mobile Miter Saw Stand with Mounting Braces.

www.homedepot.com

Those stands and the Bosch table saw riser stands are legendary.I love my Dewalt compound slider and haven't really noticed any inaccuracies after getting it tuned in. I've also transitioned into more construction type projects for other people than woodworking so that may be part of it. It is really bulky because it has the two tubes for the slider unlike the Bosch style with the articulating arm.

I just leave it attached to this, fold it up and stash it in the corner. This stand might be my second favorite "tool" purchase lately behind the track saw. If you want to take the saw off, it's just two large tabs holding it in place. Plus I can wheel it outside to do the cutting and not make a mess.

RIDGID Foldable Mobile Miter Saw Stand with Mounting Braces AC9946 - The Home Depot

Complete all your jobsite works easily and efficiently with the addition of this excellent RIDGID Universal Mobile Miter Saw Stand with Mounting Braces.www.homedepot.com

Unless I'm crosscutting something over 30" in length I'd much rather do it on a table saw. A radial arm saw is better yet I think if you can find one and have the space for it. Those things are an endangered species though. As my brother in Christ AvE would say:I like to be able to draw the cross cut across the board face once before completely cutting. With hard woods I find that trying to cut it in one sweep results in lots of blade chatter, blade bend and blow outs.

In a shop a non slide makes sense if you have a nice laser or light for accuracy. I think if I had the money I would get a radial arm saw.